Plastics Industry Sensors

Thermocouples for Plastic Molding and Extrusion

These are general purpose thermocouples whose primary usage is on the barrels, nozzles and molds of plastic injection and plastic extrusion machinery. They are available in a wide variety of lengths, configurations and calibrations to meet virtually any need in the plastics manufacturing industries. Resistance temperature detectors (RTDs) are also available.

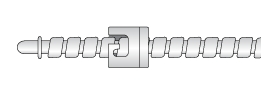

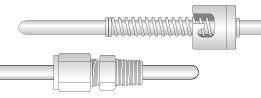

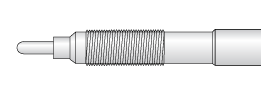

Armor Style Varidepth®

Adjusts to various depths by adjusting the cap up or down along the armor, eliminating the need to stock several fixed immersion depth sensors. 750° F Max.

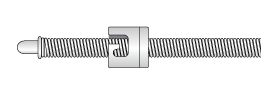

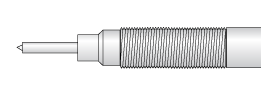

Spring Style Varidepth®

Adjusts to various depths by adjusting the cap up or down along a 6" or 12" spring, eliminating the need to stock several fixed immersion depth sensors. 750° F Max.

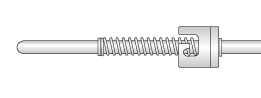

Fixed Immersion

Immersion depth is fixed for your application with a spring loaded bayonet cap for quick insertion and detachment. Custom lengths available to meet your specifications. 900° F Max.

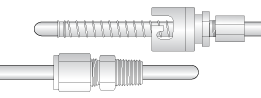

Adjustable Immersion

A compression fitting or compression mounted bayonet spring assembly allows user to determine the final immersion depth. 900°F Max.

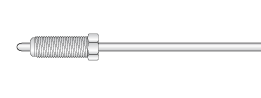

Rigid (Fixed or Adjustable)

Immersion depth fixed to your specifications or adjustable with a compression fitting during installation. Rigid tube with no lead wire.

900° F Max.

General Purpose

Designed to be a simple plain sheath style thermocouple with no permanently attached fittings. Several OD's available including 4mm.

900° F Max.

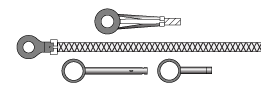

Ring and Lug Type

Measures the surface temperature such as a barrel or mold. These are placed over a threaded stud and secured with a nut. 900° F Max.

Non-Immersion

The non-immersion nozzle melt single element thermocouple is available with 1/4-28 thread, stainless steel, rotatable fitting. The probe is 1/8" OD, closed end, grounded.

Nozzle Melt

Designed for injection molders, these seal against the high pressures encountered in the nozzle. Senses the actual temperature of the plastic just before it is injected in to the mold. 750° F Max.

Melt Bolt

Melt Bolt thermocouples are used on extruders and injection molding machines. The immersion tip provides direct melt temperature measurement. Available in rigid length mineral insulated or flexible armor with lead wire.

Retractable Melt Bolt

Measures melt stream temperature under working conditions. It can be installed wherever standard melt bolt thermocouples are used. Bolt lengths of 3", 5" and 7" are available. Adjustable by turning the rotating adjustment screw.